Leaking pipes and fittings can lead to high utility bills, wastage of an important natural resource and present a hazard in your home. While the best way is to stop a leak before it happens, sometimes it just happens and you therefore need to get on top of things.

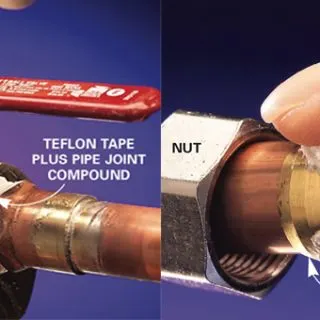

Most pipe fittings are made of brass with some of the most common being union tees, elbows, crosses and couplings among others. If it is a threaded brass union leaking or any other threaded brass fitting for that matter, there are two effective ways that can help stop the leaks:

- By using Teflon tape

- Using pipe thread compound

Steps to follow when using Teflon Tape

With this option, you need to:

- Tightly wrap the tape around the male pipe, 3-5 times over and clockwise in the threads’ direction

- Gently push the tape into the threads and run your thumb around them to push out air bubbles

- Then tightly screw the fittings back together

Steps to follow when using pipe thread compound

When using the pipe thread compound, you need to:

- First Start by unscrewing the two threaded fittings joined together

- Then clean any old sealant or grit from both the female and male threads and dry the threads using a towel

- Put some few pipe thread compound drops on the male fitting’s threads

- Tightly screw the fittings back together and wipe around them with a towel to rid of any excess thread compound

- Allow the compound to dry completely before running any water

Using a plumbing sealant for leaks is usually effective and would put a stop to the leaks from your threaded brass fittings.

Many brass fittings are connected on copper pipes using a compression fitting, which is composed of a ferrule (inner compression ring) and an outer compression nut. With compression fittings, thread sealants are not necessary since it’s the compression of the ferrule between the pipe and nut that seals.

To stop the leakage you only need to gently tighten the compression nut. However in some situations, like if the threads on the fitting or nut are damaged, replacing the fitting is the only solution to the problem.

How to stop leaks on threaded copper fittings

Poor sealing of threaded pipe fittings causes leaking. To address this problem you need to ensure the leaking threaded copper fitting is properly sealed. Just like with the brass fittings, use a thread tape or thread compound to seal any leakage coming through the threads.

If the threads on the copper fittings are badly damaged and the sealant does work then you may need to replace the fitting.

How to stop a leaking pipe with water in it

If your pipe still has water in it then the first step to stopping the leak is cutting off the mains connection to this pipe. That would reduce the amount of water that would be flowing through the pipe. You then need a towel to place it underneath the leaking pipe you want to work on. The towel will help absorb some of the water leaking.

When doing plumbing connections it is important you do them correctly if you want to avoid any leaks. Learn how to connect copper pipe to threaded brass fitting or compression fitting if you have to. It could help avoid leaks arising from improper connections.

Is Pipe Sealant Better than Teflon Tape?

Pipe sealant is easy to find, reasonably simple to use, and inexpensive. It works with all types of pipe and fitting materials, and it produces a strong seal. Pipe sealant is generally a more robust seal than Teflon tape, which is why plumbers and other professionals use it rather than tape for permanent seals.

The glue works by hardening as the solvent carrier evaporates, resulting in a seal that firmly adheres to both metal and plastic pipes to prevent leaking. The pipe sealant works better than Teflon tape, though the choice depends on your preference.

Can You Put Too Much Teflon Tape?

It’s not best to use too much Teflon as it can crack the female adapter. Use enough but not excess. When screwing them together, go hand tight and use channel locks or similar to tighten it ½ to ½ turns.

To use the Teflon tape, you need 3-4 wraps in the same direction as you turn on the fitting. Start wrapping at the end of the connection and wrap towards the piping keeping the tape tight. You can also add some pipe dope on top of the Teflon tape.

Can You Re-use Brass Compression Fittings?

You aren’t supposed to re-use brass compression fittings – once you make the compression fitting, usually that’s final. You can apply a compression sleeve puller to unfasten the old sleeve from the copper pipe to prevent you from cutting the pipe too short. If the copper pipe is not too disfigured from over-tightening the old fitting, you can make a good seal with the new compression connection.

For better results of re-using, make sure you maintain the right amount of torque. Hydraulics are capable of causing severe personal injuries and environmental damage if you don’t adhere to assembly instructions strictly. Again, as long as the brass fitting isn’t worn-out, it’s okay. Ensure you clean off the mating faces and don’t use tape, putty, or anything else.

Is it Okay to Mix Brass and Galvanized Fittings?

It’s not appropriate to mix the fittings; the galvanized pipe’s properties will weaken the brass’s properties. It is an excellent idea to either change or repair a pipe or joint with the identical material.